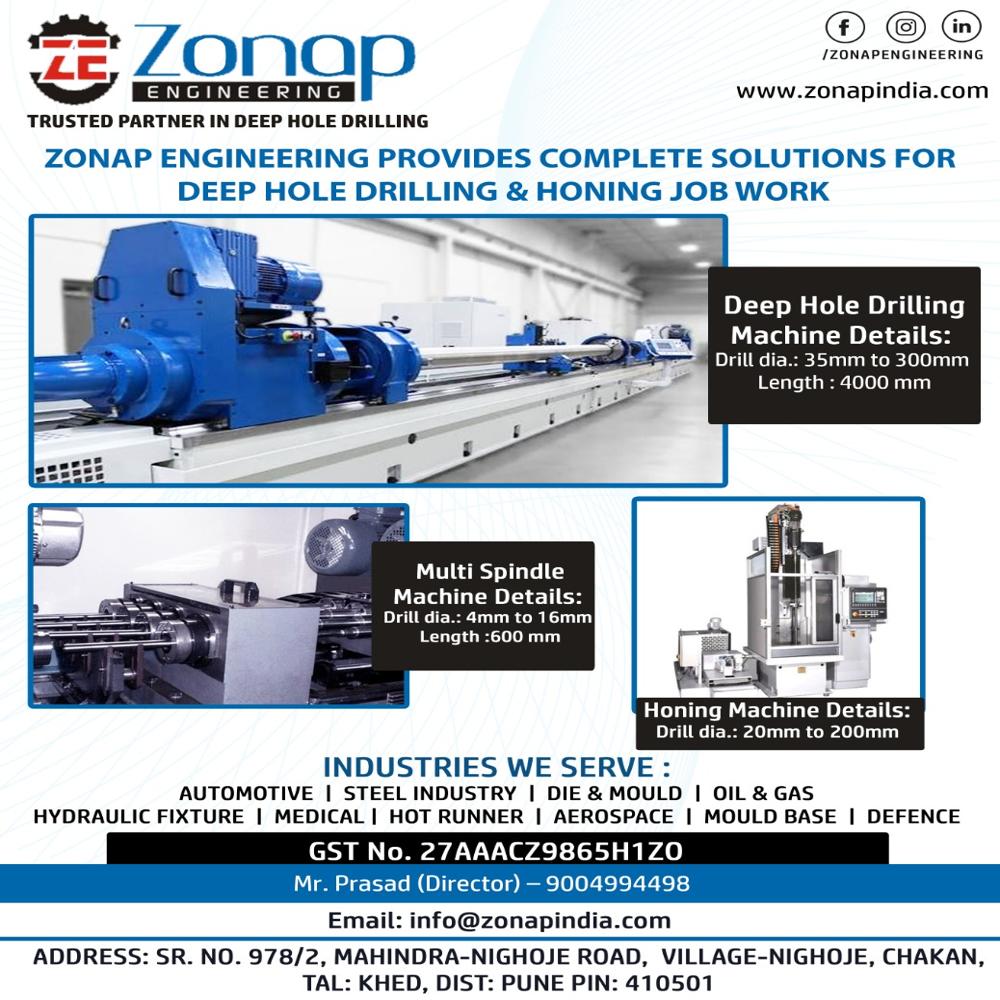

Stainless Steel Deep Hole Drilling Service

Product Details:

X

Stainless Steel Deep Hole Drilling Service Price And Quantity

- 10 Number

Stainless Steel Deep Hole Drilling Service Trade Information

- 5-10 Days

Product Description

Good quality products and services. Obtained the quality inspection certificate of China. Cooperative win-win marketing, service first, quality first. Hope to cooperate sincerely. Reasonable price. High quality. Standard machine in stock.Precision Deep Hole Drilling for Demanding Applications

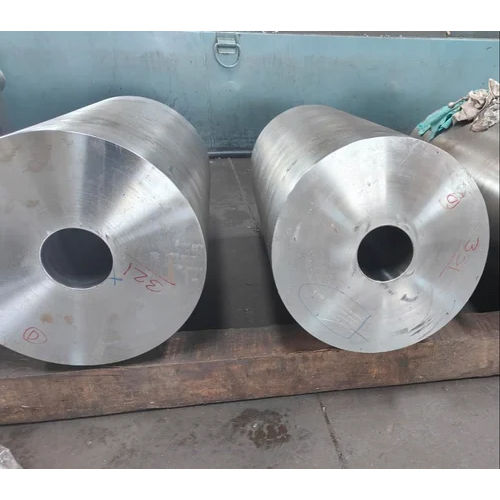

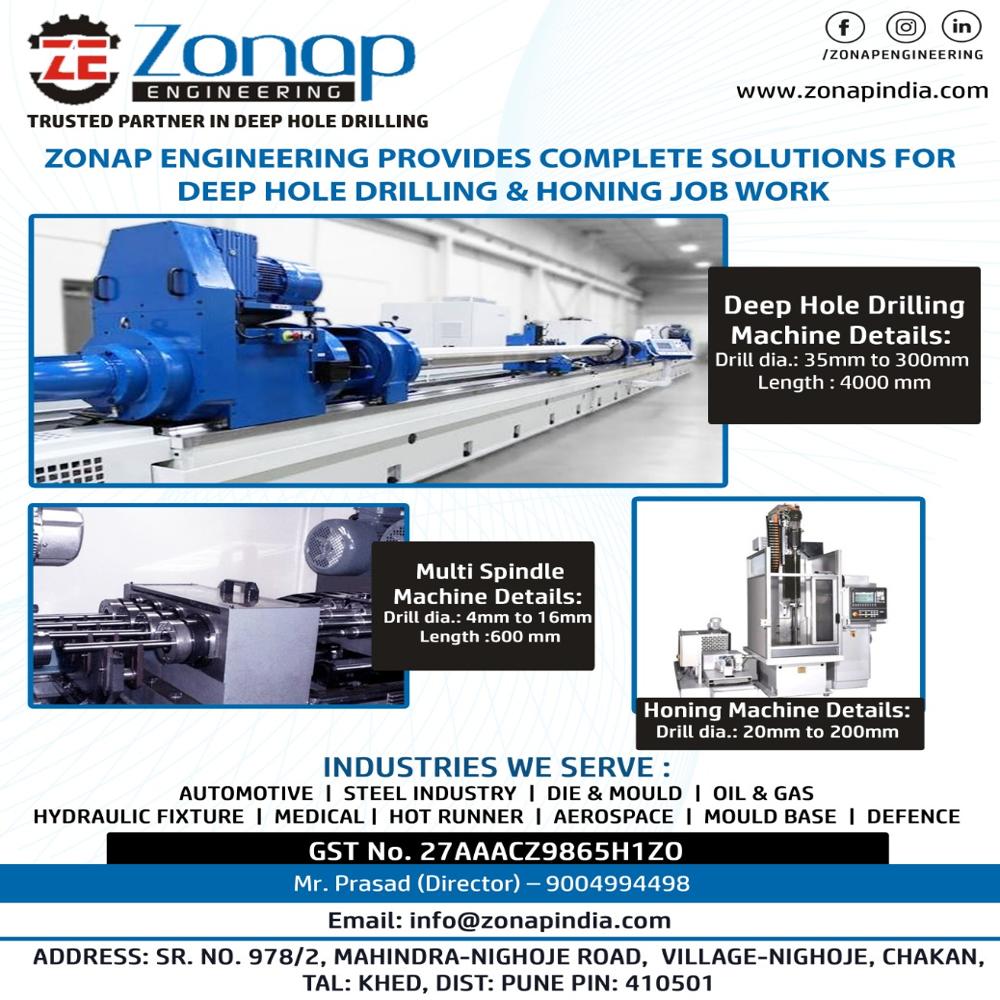

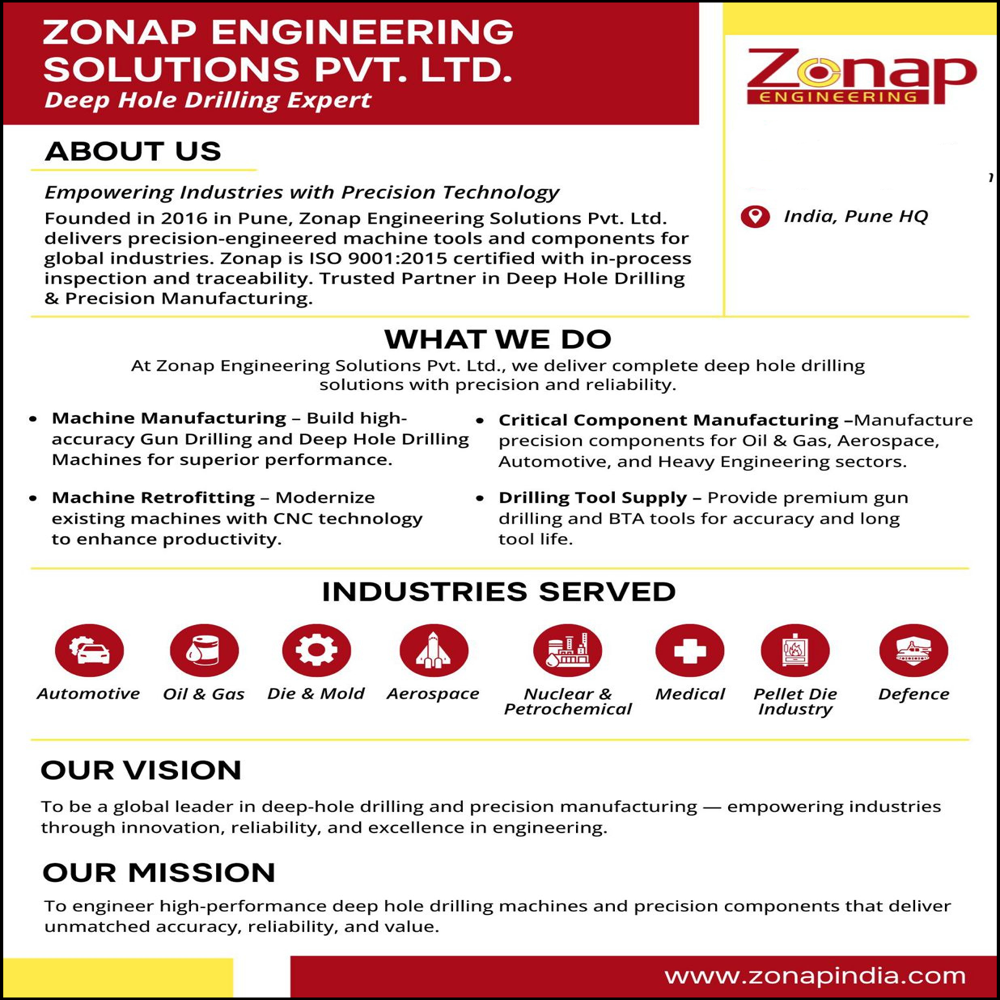

Our service specializes in stainless steel deep hole drilling that meets the rigorous requirements of sectors such as aerospace, automotive, and oil & gas. Utilizing sophisticated machinery and experienced professionals, we deliver precise and uniform holes that conform to international standards, ensuring optimal performance for your critical components.

Advanced Drilling Techniques & Quality Standards

With our expertise in gun drilling and BTA drilling methods, we achieve outstanding accuracy and surface quality. Our commitment to ISO 9001:2015 compliance assures clients of reliable, repeatable results and strict adherence to process controls, providing confidence in every job, big or small.

FAQs of Stainless Steel Deep Hole Drilling Service:

Q: How does your deep hole drilling service ensure high precision in stainless steel?

A: We achieve high precision by employing advanced gun drilling and BTA drilling techniques, strict process controls, and ISO 9001:2015 quality management systems. Our methods enable us to consistently meet tight tolerances of up to 0.02 mm and deliver excellent surface finishes.Q: What is the maximum drilling depth and the size range of holes you can provide?

A: We can drill to a maximum depth of 3000 mm. Our services accommodate holes with diameters ranging from a minimum of 5 mm to a maximum of 100 mm, suitable for a variety of engineering applications.Q: When can I expect my order to be completed?

A: Lead times vary based on job complexity and volume. After reviewing your project specifications, we provide a detailed timeline to ensure your delivery expectations are met.Q: Where is your stainless steel deep hole drilling service available?

A: We offer our deep hole drilling services across all regions of India, serving customers from multiple industries through offline service modes.Q: What is the typical process followed for deep hole drilling in stainless steel?

A: After receiving customer requirements, we review engineering designs and select the appropriate drilling technique (gun drilling or BTA). The process includes meticulous setup, precision machining, and thorough quality inspections to guarantee compliance with all specifications.Q: Can the drilling specifications be customized for specific applications?

A: Yes, we provide fully customizable drilling specifications based on your particular project needs. Our team consults with clients to define and deliver unique requirements effectively.Q: What are the primary benefits of using your deep hole drilling service for stainless steel components?

A: Key benefits include high accuracy, smooth surface finish, adherence to industry standards, and the ability to handle complex and critical applications, reducing downstream machining requirements and improving end-product quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email